Infrared Radiant Tube Heater

Model: EHL series

Model: EHL series

Country: USA

Heating broiler houses and agricultural facilities are now possible with the most energy efficient technology available in today’s marketplace. Detroit R

adiant Products is pleased to offer a full line of heaters specifically designed for the agricultural marketplace.

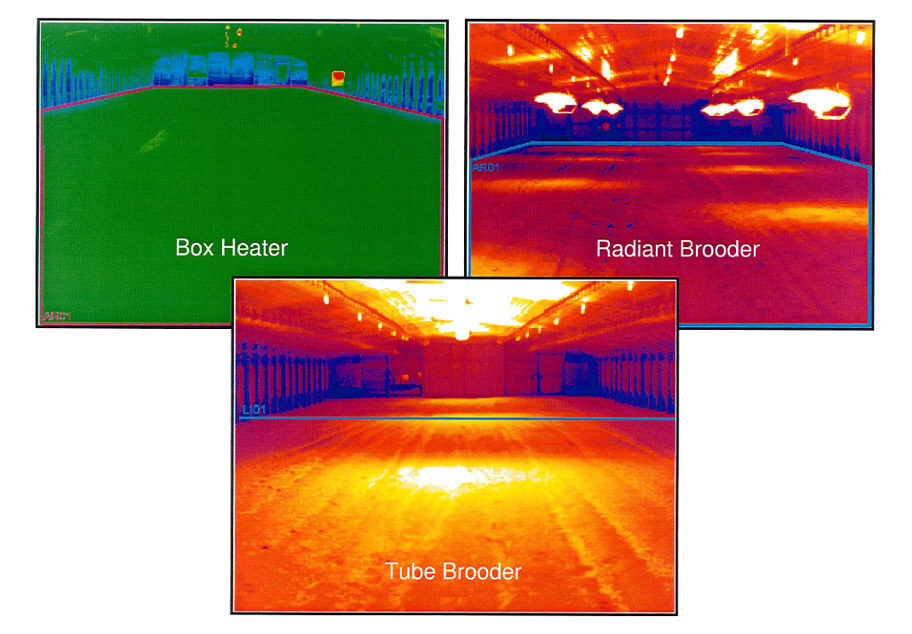

Tube heaters have known operating benefits and are commonly applied in swine, poultry, brooder and dairy applications. Further efficiencies can be achieved through the use of two stage heating equipment. This includes reduced operating expenses, reduced on-off cycling, improved animal comfort and the ability to change BTU outputs depending upon animal size and changing weather conditions. Benefits include improved animal performance, reduced fuel consumption, and improved longevity.

- > Save 20-50% on your fuel bill using radiant tube heat vs. other heating appliances

- > Reduce annual maintenance up to 90%

- > Provide superior comfort with optional two stage operation

- > Secure quiet and clean operation

Heat Pattern

Applications:

⦁ Agricultural Facilities such as Poultry, Swine, Dairy and Brooder.

⦁ Manufacturer/Warehouse

⦁ Retail Facilities

⦁ Auto Dealer

⦁ Car Wash

⦁ Indoor/Outdoor

FEATURES

⦁ Inputs of 19.0 to 60.0 kw

⦁ Available in Tube Lengths of 6710 mm to 21335 mm

⦁ Coated Titanium or Aluminized Combustion Chamber

⦁ Coated Aluminized or Optional Economy Hot Rolled Steel Radiant Tubes

⦁ Patented Two-Stage Technology

⦁ Highly Polished Aluminum Reflectors

⦁ Stainless Steel Burner

⦁ Spark Ignition System

⦁ Enameled Control Box with Plastic Cover

⦁ Operational Indicator Lights

⦁ Optional #3 Brushed Stainless Steel Control Box

⦁ Optional ‘U’ or ‘L’ Configuration

SPECIFICATIONS

⦁ BTU Range: 65,000 – 150,000 (14.7 -43.0 KW)

⦁ Gas Types: G-20, G-25 or G-31 (other gases upon request)

⦁ Tube Lengths: 20 ft. – 70 ft.

⦁ Limited Warranty: 1/3/5 (components/tubes/burner)

⦁ Combustion Tube: 4″ dia. Aluminized or Titanium Steel, Black Coated Radiant Tubes 4″ dia. Aluminized Steel, Black Coated

⦁ Certification: CE, Outdoor Approval

What is Infrared?

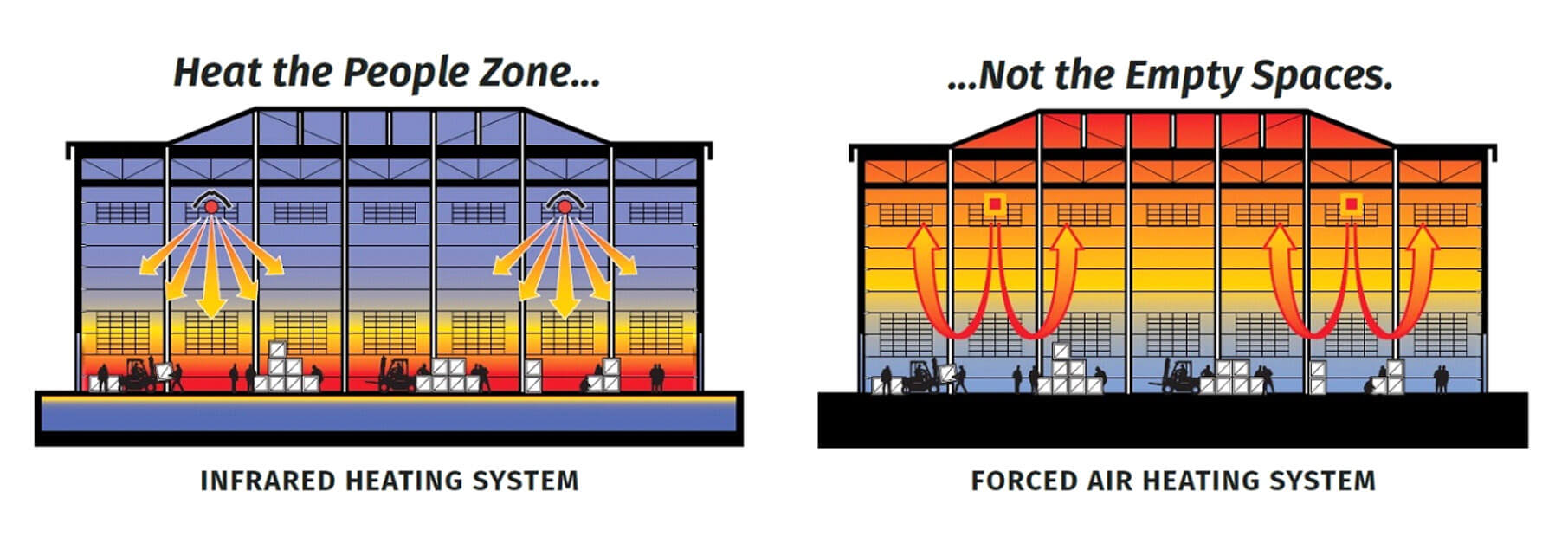

Infrared heats people, floors, walls, and other surfaces directly without heating the air first.

The result is an instant warming effect, similar to the effect felt when the sun emerges from the clouds on a chilly day. When infrared heating is used in an enclosed building, objects in the space absorb the emitted infrared energy. Once absorbed, the energy is converted into heat which in turn warms the surrounding air. With convection space heating, the air must first be heated and then circulated in order to warm objects and people in the space.

Heat the floor, not the ceiling

Through various methods of heat transfer (radiation, re-radiation, conduction, and convection) the air is heated secondarily as it passes over the warm concrete. Therefore, the heaters can be controlled by air temperature sensing thermostats.

This method of heating, as opposed to filling a room with warm air (such as a forced air unit) allows the source of heat to begin at the floor level and not the ceiling. This makes it the most efficient and effective method in which to heat under the diverse conditions present in warehouses, storerooms, and even the most immense structures imaginable.

The Theory of Infrared Heat

The Types of Infrared Heaters

General Infrared Heater Design Principles

Infrared Heater Safety and Installation, Operation, and Maintenance Practices

Key Construction and Operational Features

Efficiencies, Green, and LEED

Engineered Infrared Radiant Vacuum Systems

Electric Infrared Element Comparison